Operation-Manual-LST-GM1

Application

- Solid Waste Lanfills

- Sewage Treatment

- Anti-seepage Project

- Chemical Mining

- Water Conservancy

- Aquacuture

Precautions

Parameter

Please confirm that the machine is turned off and unplugged

before disassembling the welding machine so as not to be

injured by live wires or components inside the machine.

The welding machine generates high temperature and high heat,which may cause fire or explosion when used incorrectly,especially when it is close to combustible materials or explosive gas.

Please do not touch the hot wedge (during weldingor when the welding machine has not completely cooled down) so as not to burn.

The power supply voltage must match the rated voltage marked on the welding machine and be reliably grounded. Connect the welding machine to a socket with a protective ground conductor

In order to ensure the safety of the operators and the reliable operation of the equipment, the power supply at the construction site must be equipped with a regulated power supply and a leakage protector.

The welding machine must be operated under the correct control of the operator, otherwise it may cause combustion or explosion due to hightemperature.

It is strictly forbidden to use the welding machine in water or muddy ground, avoid soaking, rain or damp.

| Model | LST-GM1 |

| Rated Voltage | 230 V / 120 V |

| Frequency | 50 / 60 Hz |

| Rated Power | 1400 W |

| Welding Speed | 0.5 - 6.0 m/min |

| Heating Temperature | 50 - 450 ℃ |

| Welding Pressure | 100-1000 N |

| Material Thickness Welded | 0.2 mm - 2.0 mm(Single Layer) |

| Overlap Width | 12 cm |

| Seam Width | 15 mm *2, Interior Cavity 15mm |

| Seam Strength | ≥ 85 % Material |

| Net Weight | 9.0 Kg |

| Membrane Laying Ways | Membrane laying way by oneedge against the other edge |

| Digital Display | Temp. & Speed Display |

| Certificate | CE |

| Warranty | 1 Year |

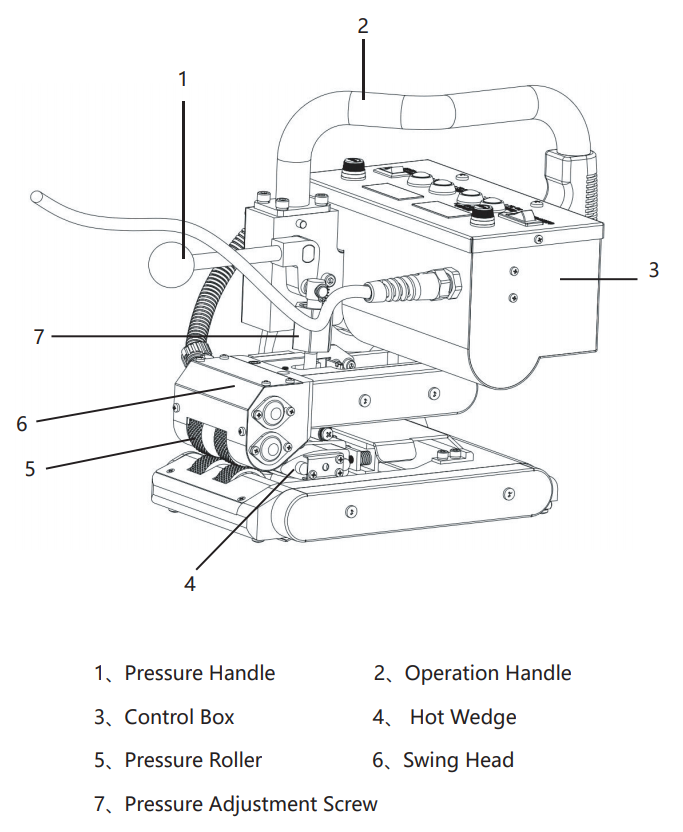

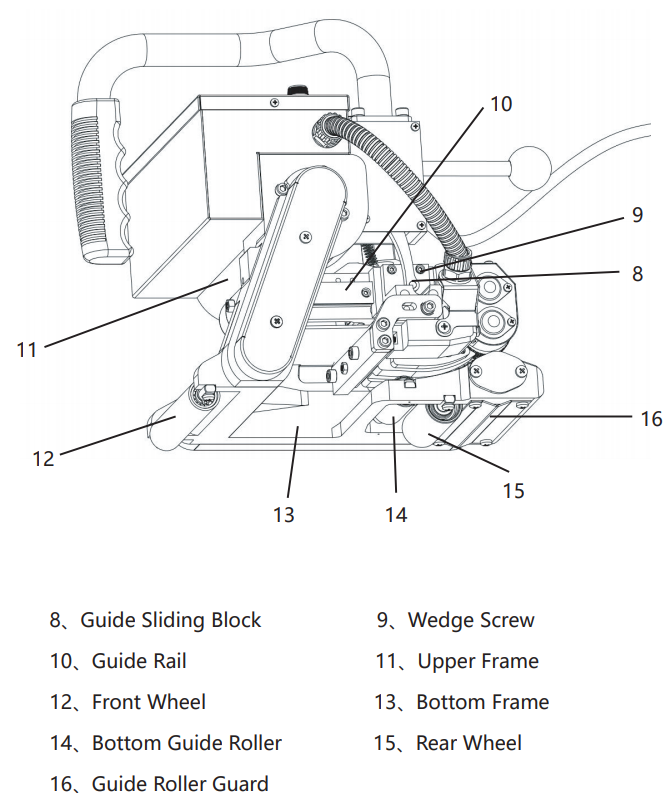

Main Parts

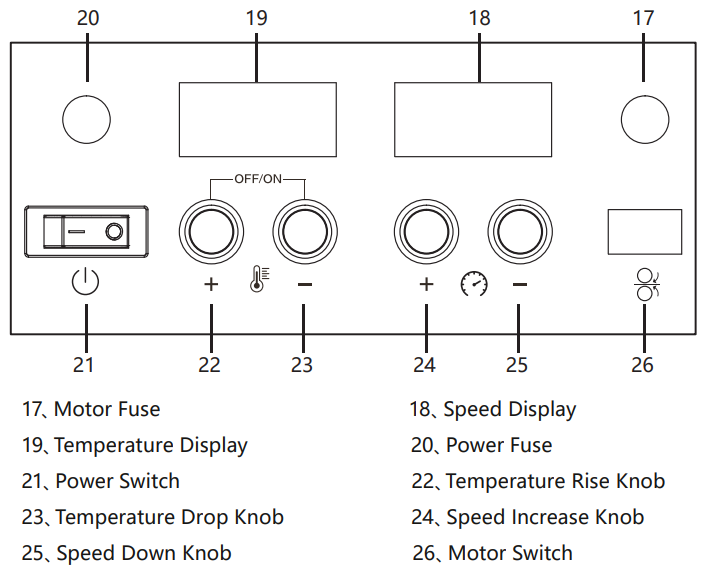

LST-GM1 Control Panel

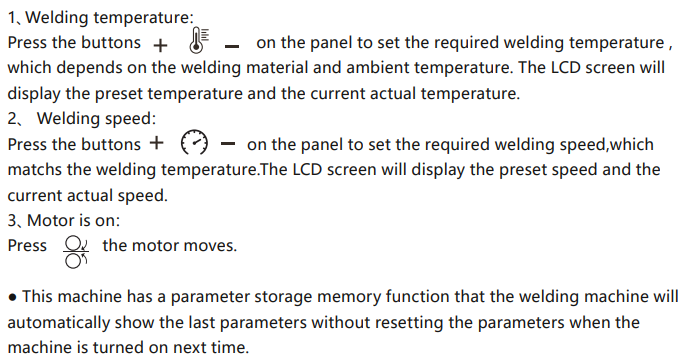

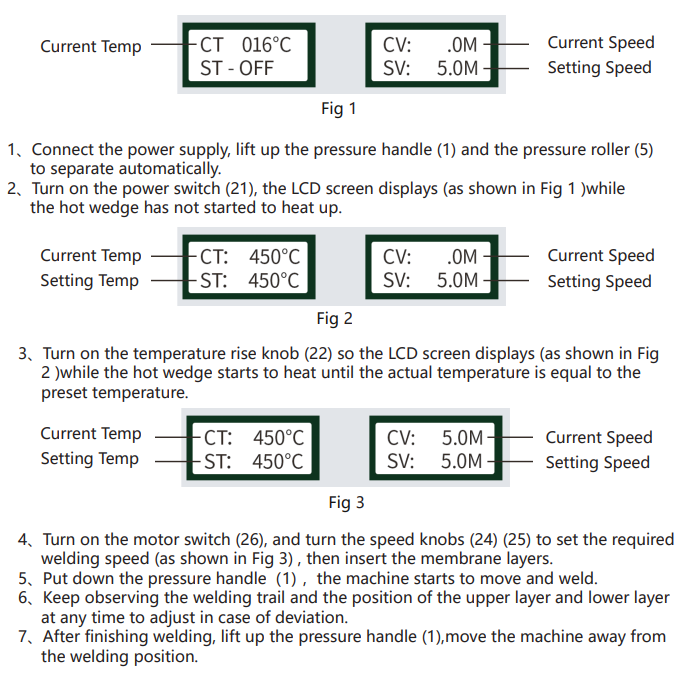

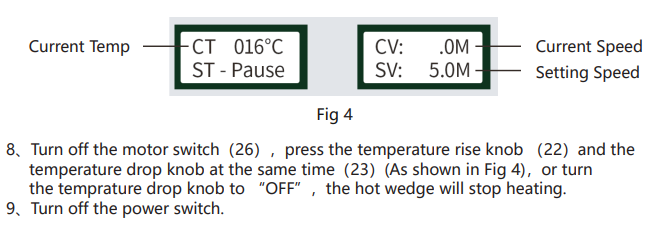

LST-GM1 Operation Steps

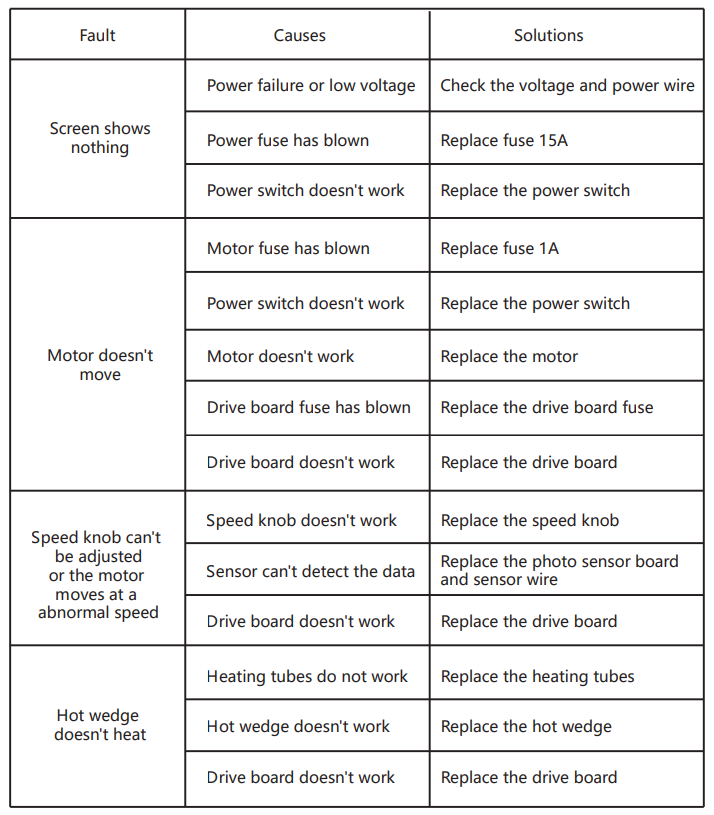

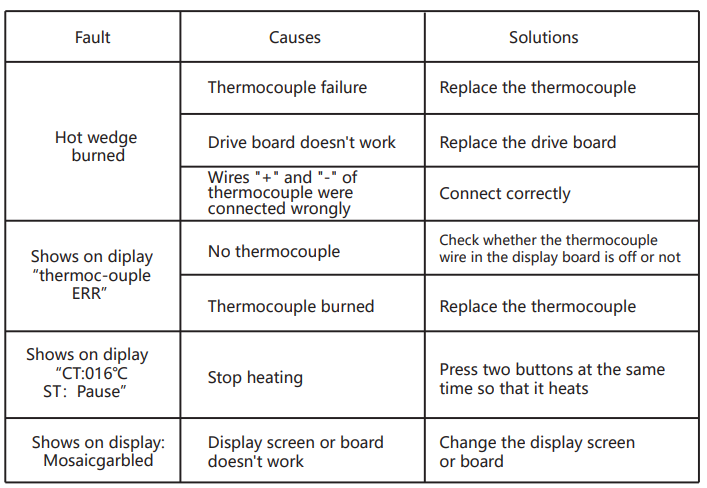

Fault & Solutions

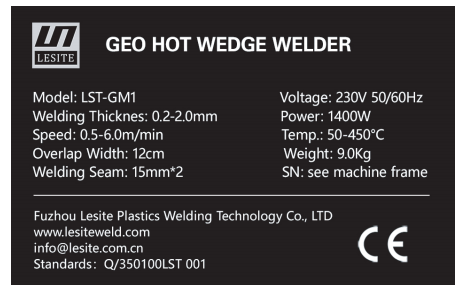

LST-GM1 Nameplate

The model identification and serial number identification are marked on the nameplate of the machine you choose. Please provide these data when consulting Lesite Sales and Service Center.

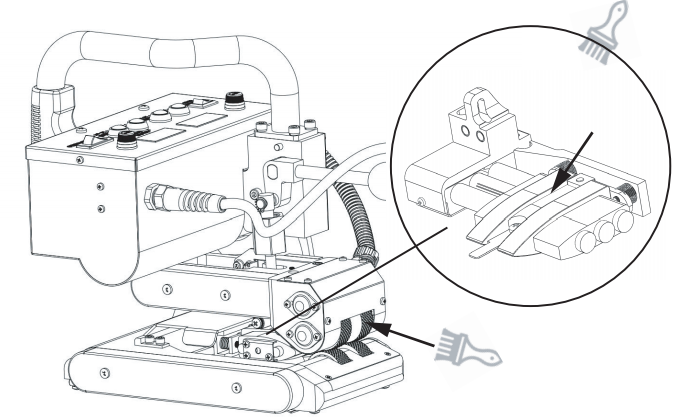

Maintenance

Do clean the hot wedge and pressure rollers after welding.

Quality Assurance

This product guarantees a 12-month shelf life from the day it is sold to consumers. We will be responsible for failures caused by material or manufacturing defects. We will repair or replace defective parts at our sole discretion to meet the warranty requirements. · The quality assurance does not cover damage to wearing parts (heating elements, carbon brushes, bearings, etc.), damage or defects caused by improper handling or maintenance, and damage caused by falling products. Irregular use and unauthorized modification should not be covered by the warranty.

Standards

The company declares that the products manufactured and marketed by the company meet the requirements of the following enterprise implementation standards. Standards:Q/350100LST 001.

Maintenance

· It is strongly recommended to send the product to Lesite company or authorized repair center for professional inspection and repair.

· Only original Lesite spare parts are allowed.